Vertical Pumps

Space-efficient vertical pump solutions for deep well and sump applications

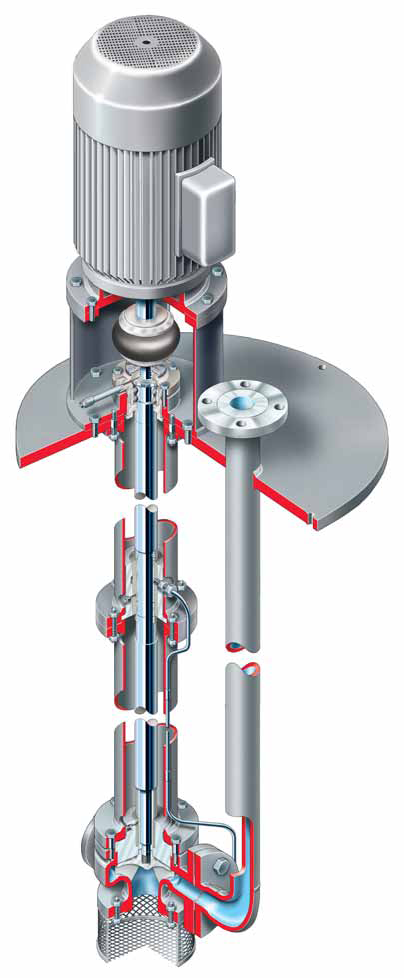

CPXV ISO & API Vertical Sump Pump

The Flowserve CPXV is a vertical sump pump incorporating state-of-the-art hydraulic design for efficient and reliable service. The CPXV can be customized to meet a wide range of needs. Compliant with ISO 5199, the CPXV is available in 40 hydraulic wet-ends and a wide variety of materials of construction. It is also available with multiple mechanical seal options and sump depths.

Operating Parameters

API 610 Configuration

The Flowserve CPXV vertical sump pump is also available in an optional API 610 compliant model, specifically engineered for the hydrocarbon and petrochemical processing industries. Rectangular or circular soleplates are standard. A full ANSI 150/300 lb RF soleplate is optional.

Standards Compliance

The CPXV is CE marked and compliant with applicable European directives, such as ATEX.

Modular Construction ensures installation flexibility with a standard column length of 0.5 m (1.6 ft), which equates to a minimum sump depth of 0.7 m (2.3 ft)

Additional Column Lengths are provided up to a maximum of 10 m (32 ft) Heavy-Duty Thrust Bearings with axial adjustment made at soleplate level

Recessed Impeller version is available for enhanced solids handling capability. Suction Strainer optional

Fully Jacketed version is available for molten sulfur applications.

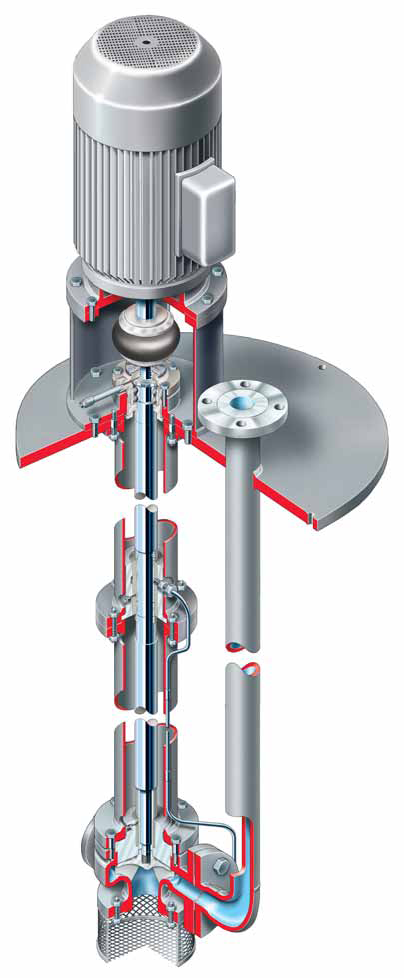

VTP Vertical Turbine, Wet-Pit Pump

The Flowserve VTP is a single casing, diffuser type vertical turbine pump that is usually installed in wet-pit or deep well applications where NPSH available is ample.

VTP Configurations

Construction Options

Sealing Configurations

Drive Options

VTP Applications

Operating Parameters

Lubrication Options

Product Lubrication

Utilizes open lineshaft construction allowing lineshaft bearings to be lubricated by pumped liquid

Enclosed Oil Lubrication

Isolates the lineshaft and bearings from the pumped liquid minimizing maintenance in abrasive services. Alternative lubricants such as clean water or grease can also be used with enclosed lineshaft construction

Rebowl Services

Flowserve can revitalize the performance of aged VTPs and reduce total operating costs. Whether for competitor or Flowserve pumps, upgrades will reduce power consumption, downtime and maintenance costs while extending the pump life.

Need Vertical Pump Solutions?

Our vertical pump specialists can help you select the right solution for your deep well and sump applications.