Multistage Pumps

High-pressure pump solutions with multiple impellers for demanding pressure applications

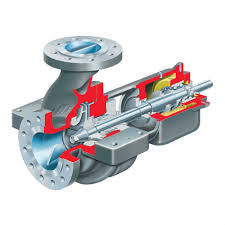

DMX Between Bearings, Multistage, Axially Split Pump

DMX pump is a horizontal, multistage, axially split, near centerline-mounted pump. The the fully compliant API 610, latest edition is used for applications involving high-flow, high-pressure movement of water, crude oil, CO2 and other hydrocarbons.

The basic pump design, consisting of back-to-back mounted impellers operating in heavy-duty double volute casings, inherently results in optimum axial thrust and radial thrust balance over the full operating range.

Application

Operating Parameters

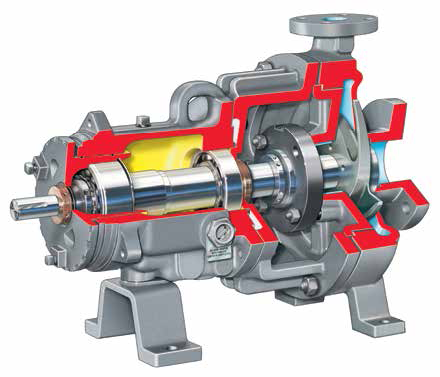

WDX Multistage Ring Section Pump

The WDX type pump is a horizontal, multistage, radial split case, vaned diffuser type centrifugal pump equipped with a special suction impeller for low NPSH. It can be used with motor, steam turbine and gasoline or diesel engine drives.

The WDX pumps are of modular construction with identical stages being stacked axially to achieve the desired pressure output. Four high strength external tie rods connecting the two end casings hold them together. A variety of optimal features and materials allow it to fit a wide range of applications such as boiler feed or reverse osmosis.

Various orientations for the radial suction and discharge nozzles are allowed every 90° except towards the bottom.

They are available in the following configurations

WDXR

WDXC

WDXE

WDXS

Operating Limits (depending on pump size, material column and temperature)

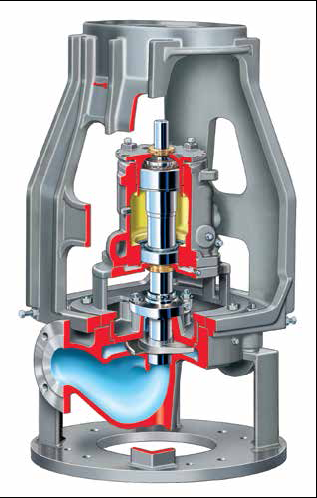

WXH Utility Grade Multistage, Ring Section Pump

The WXH multistage ring section pump is a heavy-duty, between bearing pump that is very well suited for combined cycle plants where severe cycling, cold start-up and thermal transient conditions are commonplace. It is frequently used in boiler feed and start-up boiler feed in conventional power stations as well. Its hydraulic coverage also gives it broad application in alternative power generation, including concentrated solar power and biomass plants.

In addition to power generation, the WXH can be effectively configured for high-pressure descaling service in steel mills as well as applications in the broader chemical processing industries.

Typical Applications

Power generation

Steel mill descaling

Chemical processing

Operating Parameters

Need Multistage Pump Solutions?

Our multistage pump specialists can help you select the right high-pressure solution for your demanding applications.