Veg Oils

Fatty acids synthesis and processing solutions for vegetable oil industry

Vegetable Oil Industry Solutions

Comprehensive pump solutions for fatty acids synthesis and processing in the vegetable oil industry.

Fatty Acids

Fatty Acids Synthesis & Processing

In fatty Acids synthesising and processing industry, pumps are used in mechanically moving contents between tanks.

Pump Selection Criteria

Centrifugal pumps or Positive displacement pumps such as gear pumps can be used but one should take care to install a strainer ahead of the pump when pumping out of a tank car or storage tank.

Material Considerations

However one must remember to select the right type of stainless steel as there is tendency of stainless steel to gall.

Pump Requirements for Fatty Acids Processing

Mechanical Seals Preferred

Pumps with mechanical seals are preferred for fatty acids processing applications to ensure reliable sealing and prevent contamination.

Strainer Installation

Install a strainer ahead of the pump when pumping out of a tank car or storage tank to protect the pump from debris and contaminants.

High Temperature Resistant Valves

Valves must be high temperature resistant to handle the elevated temperatures encountered in fatty acids processing operations.

Stainless Steel Selection

Select the right type of stainless steel as there is tendency of stainless steel to gall in fatty acids applications.

Pump Types for Vegetable Oil Processing

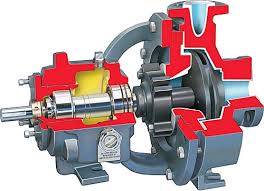

Centrifugal Pumps

Application: General transfer operations

Advantages: High flow rates, low maintenance

Suitable for: Low to medium viscosity oils

Configuration: With strainer protection

Positive Displacement Pumps

Type: Gear pumps, screw pumps

Advantages: Constant flow, high pressure capability

Suitable for: High viscosity fatty acids

Configuration: With mechanical seals

Vegetable Oil Processing Applications

Oil Extraction

Fatty Acids Synthesis

Refining Process

Degumming

Neutralization

Bleaching

Deodorization

Storage & Transfer

Technical Specifications

Flow Capabilities

Flow Rate: 1 to 2000 m³/h

Viscosity: Up to 500,000 cP

Pressure: Up to 40 bar

Suction: Up to 300mm diameter

Operating Conditions

Temperature: -20°C to +300°C

Materials: SS316L, SS304, Duplex

Sealing: Mechanical seals preferred

Environment: Food grade applications

Standards & Compliance

Food Safety: FDA, USDA compliant

Hygiene: 3A sanitary standards

Quality: ISO 9001, HACCP

Materials: Food grade stainless steel

Vegetable Oil Processing Stages

Crude Oil Processing

Oil Extraction

Mechanical extraction and solvent extraction processes requiring specialized pump systems.

Crude Oil Storage

Transfer of crude vegetable oil from extraction to storage tanks with appropriate filtration.

Pre-treatment

Degumming and phospholipid removal processes requiring precise chemical handling.

Refined Oil Production

Neutralization

Caustic soda treatment for free fatty acid removal with precise chemical metering.

Bleaching

Clay treatment and filtration processes for color and impurity removal.

Deodorization

High temperature vacuum deodorization requiring specialized high-temperature pumps.

Key Benefits for Vegetable Oil Industry

Product Quality

Food Grade Materials

FDA and USDA compliant materials ensuring food safety and product purity.

Contamination Prevention

Mechanical seals and proper material selection prevent contamination of vegetable oils.

Temperature Control

High temperature resistant valves and pumps for deodorization and refining processes.

Process Efficiency

Versatile Pump Selection

Both centrifugal and positive displacement pumps available for different applications.

Protective Filtration

Strainer installation ahead of pumps protects equipment from debris and extends service life.

Material Compatibility

Proper stainless steel selection prevents galling and ensures long-term reliability.

Need Vegetable Oil Processing Solutions?

Contact our specialists for pump solutions designed for vegetable oil and fatty acids processing. Our equipment handles mechanically moving contents between tanks with proper material selection and mechanical seals for food grade applications.